In light of saving our environment, we remain dedicated to minimizing any adverse effects to the environment from our operations.

MPRL E&P is committed to demonstrating appropriate and sincere respect for the environment, particularly for the prevention of any accidental loss of resources or assets likely to have an impact on the environment, company employees and communities located in the areas where we operate.

Our Strategy

MPRL E&P expects active participation in achieving its goals and commitments by all employees and managers regardless of corporate hierarchy, contractor, and/or suppliers who individually and collectively are responsible for performance across the business value chain.

- Minimize Environmental Impact

- Promote a Positive Environmental Stewardship Culture

- Be in Compliance with All Applicable Environmental Conservation Laws and Regulations

As a result the following commitments influence our strategy:

- Implement environmental management plans to monitor and manage impact as a result of our operations.

- Track and reduce emissions and consumption.

- Promote access to environmentally responsible methods and information across the organization.

- Protect the environment in the communities where we work and live.

- Strive to prevent pollution and seek improvement with respect to reducing emissions, wastewater discharge, energy consumption, resource consumption, and impacts on the environment.

- Monitor the effects of our activities on the environment and take action to address such effects where necessary.

- Openly communicate our environmental performance with our workforce, government, and the host communities through a variety of engagement methods including but not limited to, coordination meetings, disclosure workshops, Operational Grievance Mechanism (OGM), and performance reviews.

- Comply with both national legislation and industry best practices such as the UN Global Compact (UNGC) on the environment, in particular, the seventh, eighth, and ninth principles of the UNGC.

- Conduct appropriate training to ensure all our employees, managers, and executives are competent in their respective jobs and understand and adhere to this policy.

- Foster a culture that empowers and rewards everyone to act in accordance with this policy.

Our Management Framework

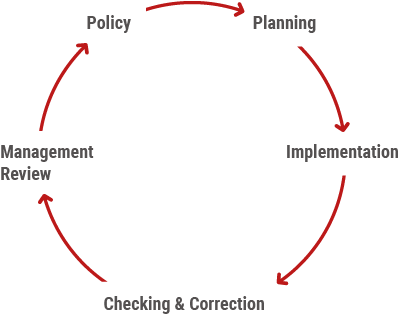

Guided by ISO 14001, MPRL E&P’s Environmental Management System Framework integrates internal policies, existing national rules and regulations, and other applicable international guidance. Continued environmental analysis and monitoring is intended to minimize the adverse impacts or consequences on the natural environment and people affected by the proposed project and/or business activity.

Fig 1: MPRL E&P Environmental Management System Framework

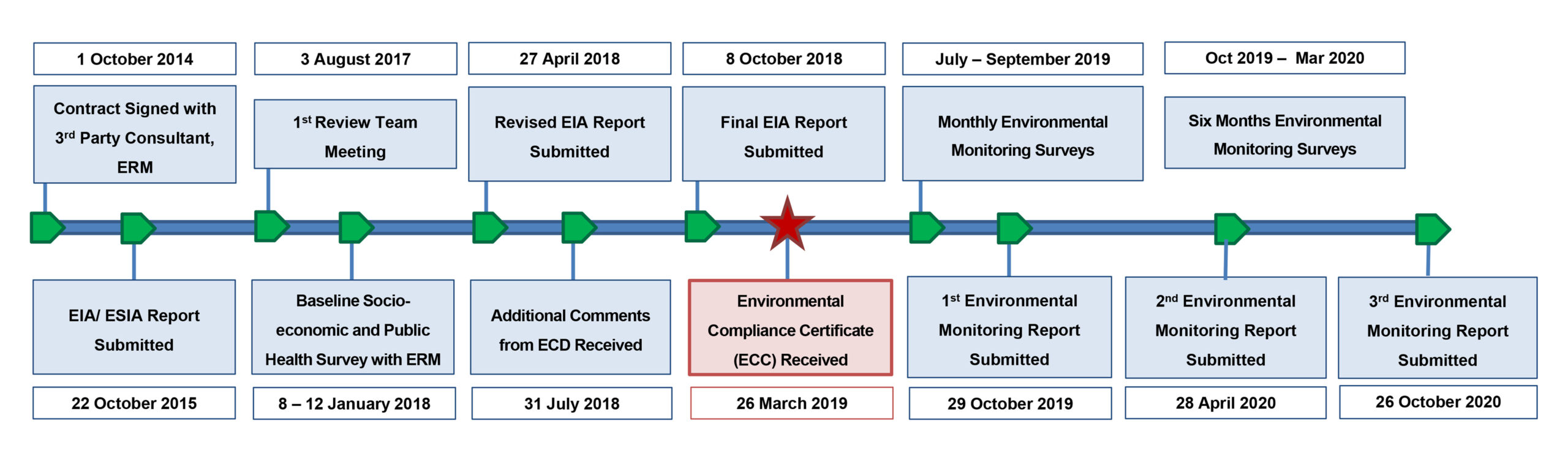

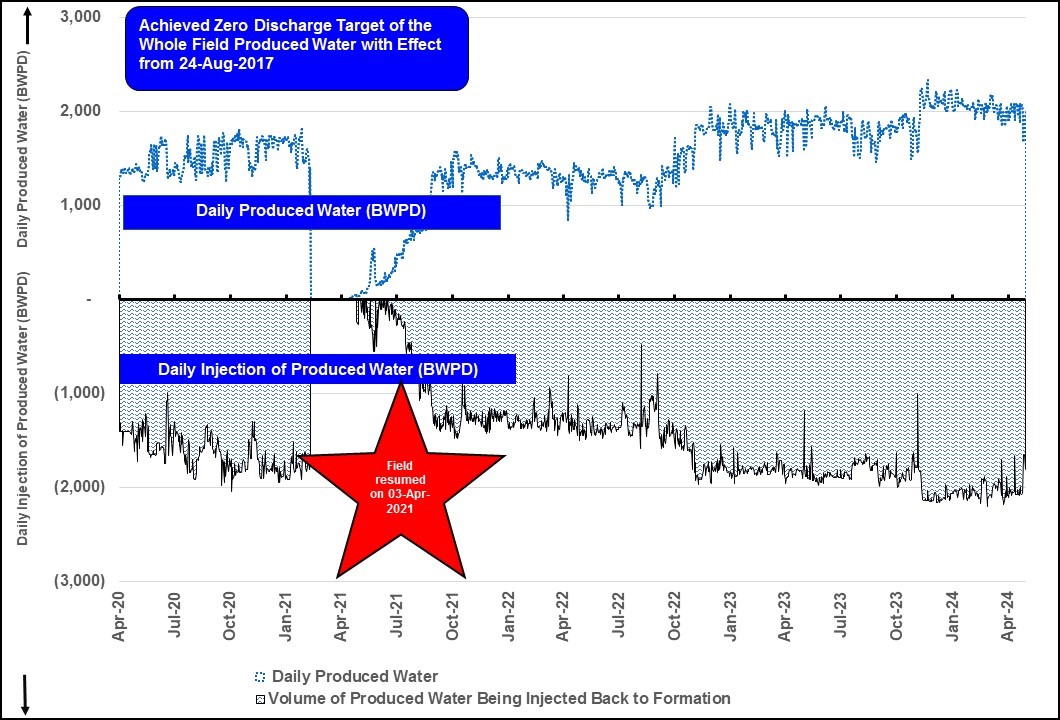

Produced Water Management in Mann Field

Produced Water Management of Mann Field – Reached ZERO DISCHARGE Achievement

As Mann Field was discovered in early 1970’s, the field becomes more mature and more water is producing from oil producing wells. The field was compartmentalized by the three major faults and other minor regular and reverse faults so that reservoir mechanism is complicated inclusive with different drive mechanisms such as solution gas drive, gas cap drive, water drive etc. Since water injection was partially applied historically, the effect of water injection and/or aquifer encroachment were observed at the producing profile.

An important question mark is that how to wisely handle the tremendous amount of unwanted produced water is an imperative task in order to minimize or avoid the environmental impact. Prior to find out the proper way to dispose those unwanted produced water, the practice was a simple disposing method which was flowing through the field. Field is located beside Mann Creek and Irrawaddy River, it was realized that disposing water could be flowed to the river, questionable environmental impact.

This note is describing the development of produced water management that MPRL E&P is practicing currently in order to eliminate environmental hazardous issues with related to producing water daily by following methods;

- Adequate well management during well completion activities to minimize water production

- Recompletion of high water producing wells to minimize water production

- Zone Isolation (Use of downhole equipment separation techniques, where possible, and water shutoff techniques)

- Disposing produced water to shut in wells by using gravity method

- Disposing produced water to shut in wells by using injection pump

The ultimate goal of MPRL E&P to minimize environmental impact is Zero Discharge in produced water management. It is not an easy task to fulfil the target and eventually it took quite a long time more than five years. However, MPRL E&P is really initiative in order to implement environmental management plan among other onshore fields. The team recorded milestones on achievements such as fabricating and renovating all gas & oil collection stations GOCS’s, constructing waste management compound, cellar renovation and constructing double cellars at individual well sites, composting food waste, segregation of general waste, sludge management, drilling cuttings management, produce water management etc. For this progress efforts, MPRL E&P proudly brings up that the mile stone of Zero Discharge on produced water management was implemented on 24 August 2017. (Fig:1)

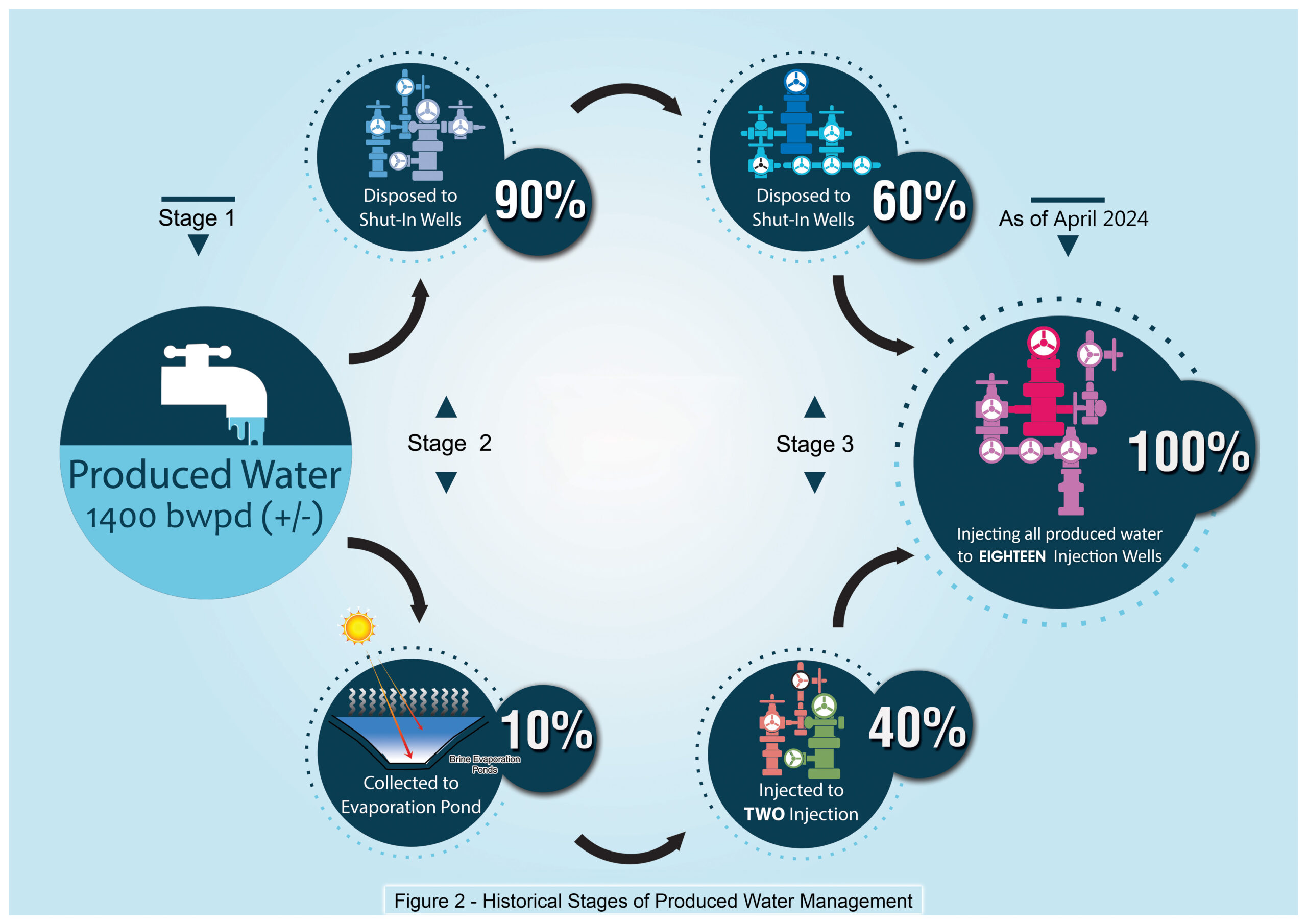

After achieving the zero discharge target, MPRL E&P started considering to extend the concept to handle produced water efficiently and effectively, that is, trying to switch from the disposal to injection all produced water in order to maximize the recoverable of reserve oil by the reservoir energy support. Reference to the operation activities, the five injection pumps are successfully injecting all volume of produced water (1400 bbl +/-) to the dedicated wells in the mid of 2019. (Fig:2)

Environmental Refurbishment Initiative

Over the past 15 years, MPRL E&P has jointly managed Mann Field with MOGE. Our partnership has strengthened over time, fostering knowledge, skills development and capacity building. Together, we understand the impact of our operations and have dedicated our time to continuously improve all operation sites to minimize any harm impacted against the environment and surrounding communities. This initiative was not part of a contractual or legal requirement but conducted as an initiative of being a responsible investor.

Before Refurbishment

After Refurbishment